Links

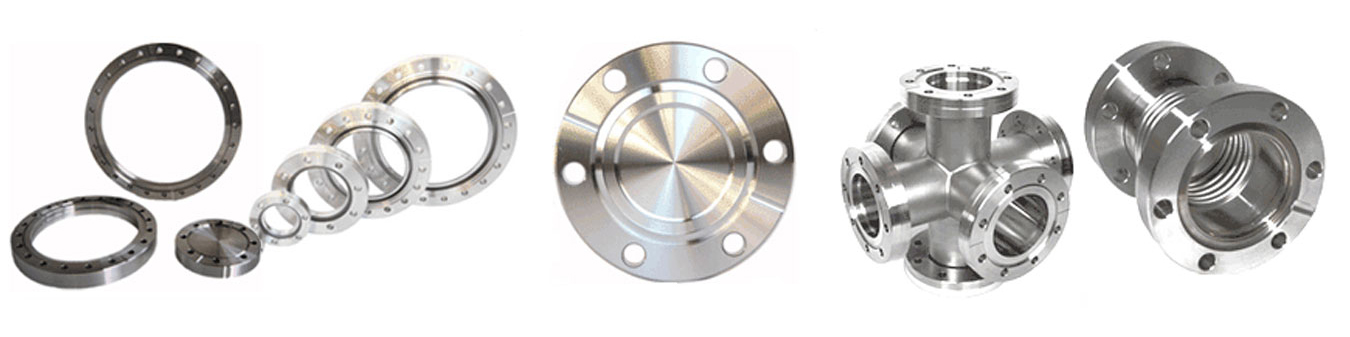

Metallic flanges are one of the central elements in vacuum systems

In a vacuum feedtrough, vacuum flanges – or metallic flanges – are standard components that are essential to the design of these systems. Flanges are the connections between the vacuum vessels and the respective components. Criteria such as tightness, stability, material and diameter are decisive in finding the right metallic flanges for your individual needs. For over 20 years, we have been offering high-quality products that reach you in absolute purity. To guarantee the satisfaction of our customers, we only use selected manufacturers for the material. Get an overview of the metallic flanges we offer.

Metallic flanges: different components for different applications

Depending on the application, there are different connection standards, which is why a distinction is made between different flange systems. We offer the following essential flange systems:

- KF flanges: these components form the standard connection for vacuum lines up to nominal size DN50 in rough, fine and high vacuum.

- ISO - Flange: With these you can make fine to high vacuum connections from a nominal width of DN63.

- Conflat CF flanges: With these flanges, you can achieve pressures up to ultra - high vacuum. To ensure this, our flanges have sharp edges that penetrates the copper gasket and forms an annular groove. This is where optimum tightness is critical.

- Quick CF - Components: On the one hand, these flanges enable fast assembly in the ultra-high vacuum range and at the same time combine the sealing principle according to ISO 3669. Here, the fast and space - saving assembly principle is particularly worth mentioning, as these flanges can be connected to already existing vacuum systems by means of an adapter. This is done by means of a clamping chain. Those users are flexible in the place of use due to the fast assembly ability. This can significantly reduce the workload of assembly personnel in radioactive environments, for example. The QCF copper seals can be used for all nominal sizes.

Choice of Material – depending on your Needs

Among the material, 316LN has the lowest magnetic permeability and retains its cutting ability even at an annealing temperature of 1050 degrees Celsius. Degassing is also possible at temperatures up to 450 degrees Celsius – provided that screws and gaskets are also designed for those temperatures.

Our offered flanges are available in stainless steel grades 304L, 316L or 316LN. We offer sizes from DN16 to DN250. The pressure range can vary from normal atmospheric pressure up to 10 - 12hPa. Next to Stainless Steel, we also offer Titanium and Kovar materials. Contact us if you have any questions.

English

English